Brand:BENTLY NEVADA

Model: 60M100

Status: New/Used

BENTLY NEVADA 60M100 Condition Monitoring System

BENTLY NEVADA 60M100

BENTLY NEVADA 60M100 Condition Monitoring System

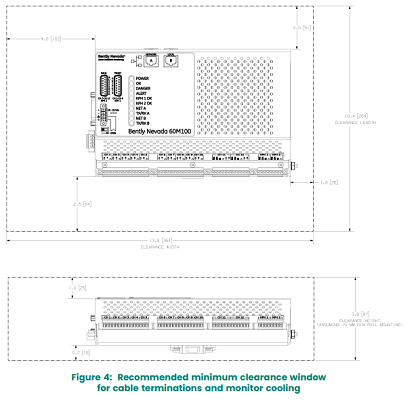

The 60M100 Condition Monitoring System continuously monitors wind turbine machine trains using sophisticated signal processing algorithms and machine operating states.The 60M100 Monitoring System, as a part of condition-based maintenance, detects defects months in advance of a potential failure.

The 60M100 Monitor can be used in several configurations:

• As an independent, standalone condition monitoringsystem.

• A networked, distributed collection of inter-operatingsystems.

• As an integrated part of a machine OEM's control andinstrumentation package.

The 60M100 monitor includes features and advantages not provided in other systems. The monitor systems have all functionality required for condition monitoring of wind turbine machine trains including signal conditioning, alarming,configuration, speed inputs, and control system communication.

The system components include: 60M100 Monitor, Adapt.wind software, Transducers and cables.

Sophisticated signal processing algorithms extract dozens of measurements and health indices from each accelerometer point and can be custom tuned to specific bearing and gear box characteristics.

60M100 Overview

The 60M100 System is designed to monitor essential characteristics and components of a wind turbine, including:

• Tower sway• Main bearing

• Main rotor

• Gear boxeso

▫ All internal bearingso

▫ All bear mesheso

▫ Debris monitoring

•Generator bearings

•Generator grounding

If you need assistance configuring your monitoring solution, contact your local Bently Nevada sales professional or Bently Nevada support (bntechsupport.com).

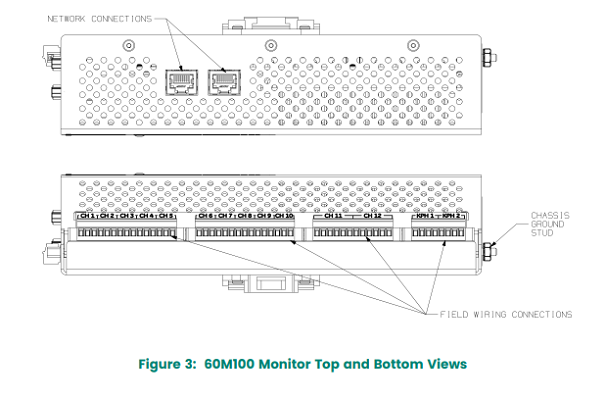

Digital Communications

The 60M100 System includes digital communication capabilities for connection to ADAPT software using proprietary protocols via Ethernet connections. The 60M100 system transmits data via Ethernet TCP/IP. You can monitor values and status

your process and control and other automation systems.

provides extensive communication capabilities of all monitored values and statuses for integration with process control and other automation systems using Ethernet TCP/IP communications capabilities. It permits Ethernet communications with other 60M100 systems and System_Software. Supported protocols include:

Modbus/TCP

Industry standard Modbus protocol over TCP.The 60M100 supports both server and client mode.

System Features

The 60M100 monitors 150 static variables producing high resolution waveform data and trendllines.

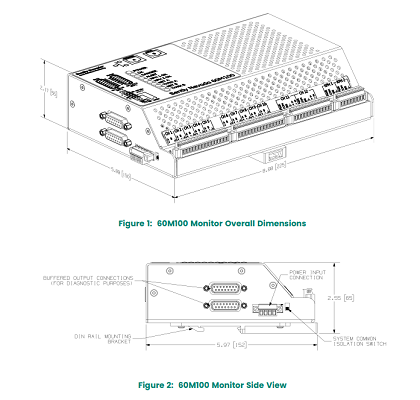

Capable of taking input from different sensor types, the 60M100 System can support up to 12 dynamic channel inputs, two Keyphasor signals, and digital communications. Channel 1 through channel 10 interface with 2-wire ICP type accelerometers. Channels 11 and 12 can be configured to interface with either 2-wire ICP type transducers or 3-wire proximity probes.Each dynamic channel can be independently configured with flexible signal processing options. The Keyphasor channels interface to either 3-wire proximity probes or other speed sensors which are powered externally.

The module provides enhanced capability for monitoring rolling element bearing machinery and gearing through its 24 bit Analog/Digital conversion and 40 kHz bandwidth design.

The 60M100 System is not a substitute for hard wired safety systems, nor does it replace the standard systems for the acquisition of operational data of the wind turbine.

Many products have not been launched yet. If you need more products, please contact us

Purchase consultation hotline: 18120742318