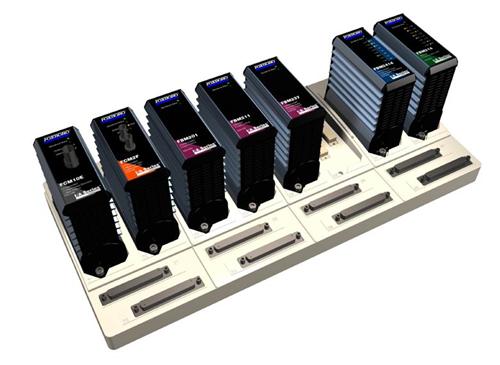

Brand:FOXBORO

Model: FBM218

Part No:P0922VW

Status: New/Used

FOXBORO FBM218 Channel Isolated 8 Communication

FOXBORO FBM218

FOXBORO FBM218 Channel Isolated 8 Communication

The FBM218 Foxboro FOXBORO controller can be upgraded to a new software version through system software upgrade. The already operational system can run the new software version to absorb technology at any time and integrate it into the existing system; Different series of processors can also run on the same network, which fully protects users from the drawbacks of early purchase and early elimination of traditional DCS.

Integration is connected to the factory information network through a standard Ethernet interface, which can transmit real-time data, historical information, report information, and various process screens. Through the intelligent field instrument (IFD) interface, digital integration with various fieldbus instruments is achieved, thereby realizing integrated management from production management information network, production control network to on-site measurement.The system reliability is ensured by multiple redundant communication networks, redundant power supply systems, mutually backup operation stations, fault-tolerant control processors, and input/output components Q using high reliability surface mount T technology, ensuring the continuous and normal operation of the system. The robust and reliable system hardware I/ASeries hardware has multi-level environmental protection capabilities. All electronic components are encapsulated in components, with no exposed electronic components, enhancing hardware resistance

Environmental corrosion and anti-static ability. The on-site control processor and I/O components can operate in an environment with pollution level 2 as defined in ISAS71.04 for G3 or IEC 664-1.

The working environment temperature of the component can reach up to 70 ℃. Remote I/O components not only enhance the resistance in signal transmission, but also effectively prevent on-site fires from affecting the control room/ The A Series system adopts a circuit design that reduces component power consumption and heat generation, and improves reliability. Metal conduction heat dissipation and T technology have reduced the size of circuits and significantly improved the reliability of equipment.

All components of the system have online and offline self diagnostic programs, and component status (red) lights are displayed. Specialized maintenance operation software can also analyze the location of faults, even to each I/O channel, and isolate faults without the need for manual judgment. Various components can be quickly replaced online and automatically started without manual intervention. Fault tolerant controller and I/O components, the controller adopts more reliable fault-tolerant technology than redundancy to ensure that each output is correct; The control logic at the driver level can reside and run within the I/O component (FBM). This configuration ensures that when two fault-tolerant controllers fail simultaneously, the control algorithm residing in the FBM can automatically switch to a hold state, keeping the on-site actuator in a safe position.

Other models: FBM215 , FBM216 , FBM216b ,FBM217 , FBM218 , FBM219 , FBM222 , FBM224 , FBM227 , FBM228 , FBM230 , FBM231 , FBM232 , FBM233